Table of Contents

Demand for plastic continues to rise in the construction industry due to its physical properties, low cost, and recyclability, according to a new report by Coherent Market Insights.

Growth could be hindered by the fluctuating price of crude oil. Polyethylene, polypropylene, polystyrene, polyvinyl chloride, and polyurethane are all derived from petroleum products.

The global building and construction plastics market exceeded $57.5 billion in 2019 and is forecast to surpass $99 billion by 2027, climbing 7.1% annually.

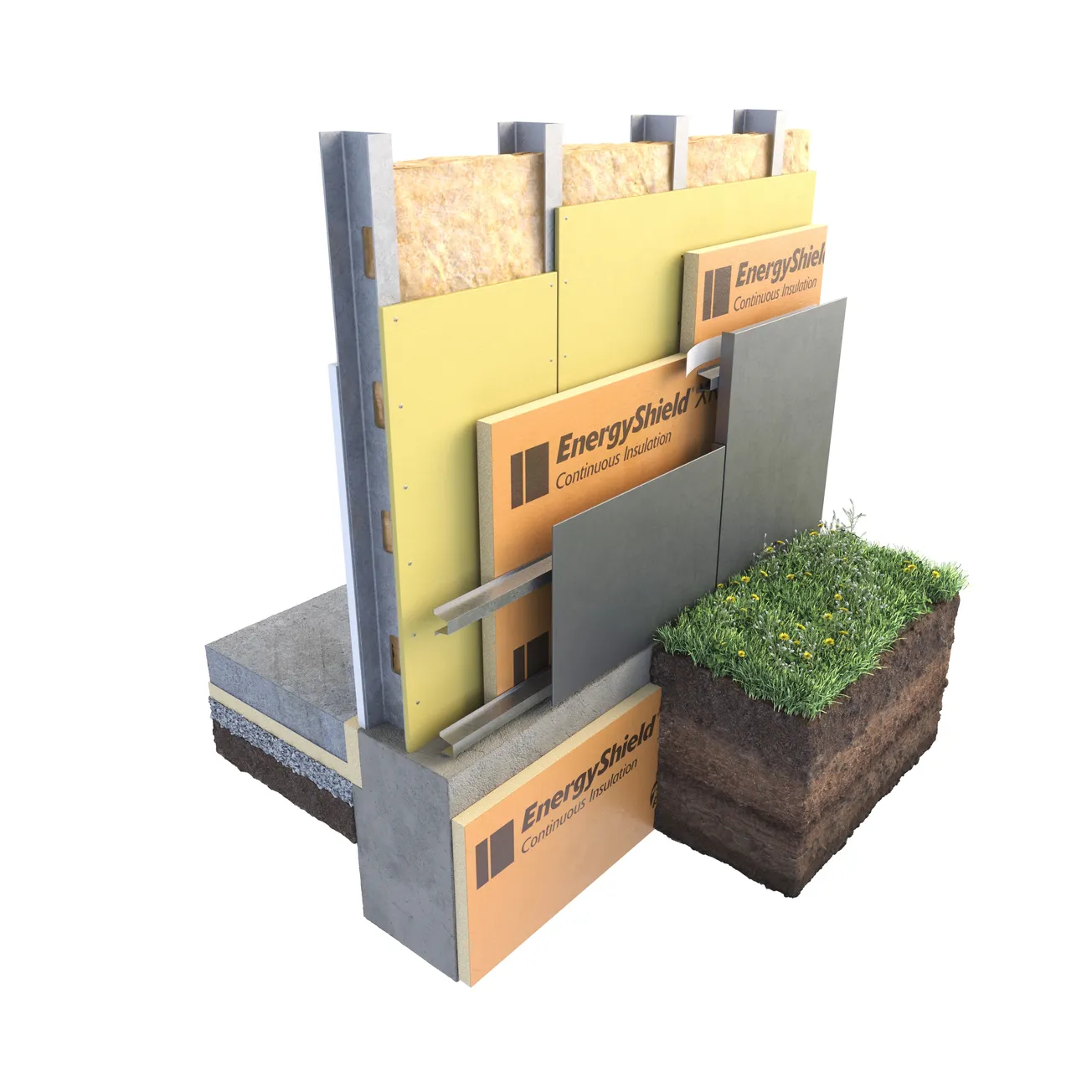

Pipes and ducts account for 34.9% of the total, followed by insulation and door fitting segments.

North America emerged as the dominant region, accounting for 37% of revenue in 2019, due to growing residential construction industry.

Increasing use of expanded polystyrene (EPS) plastics in the construction industry is a growing trend. Expanded Polystyrene (EPS) Plastics is a lightweight insulation material that offers resistance to humidity, shock absorption, and resistance to chemicals. They are widely used across the construction of roads, railway lines, bridges, and public buildings. EPS is an ideal material for use as a lightweight filler in the road to facilitate land drainage.

Around 33% of the U.S. building materials is imported from China. Factories shutdown in China in the first quarter of 2020 has impacted construction activity in the U.S. The scenario is no different on the demand side, as the privately commissioned projects have been delayed, and future spending has been reduced.